Blog and photos by Jenn Conyers

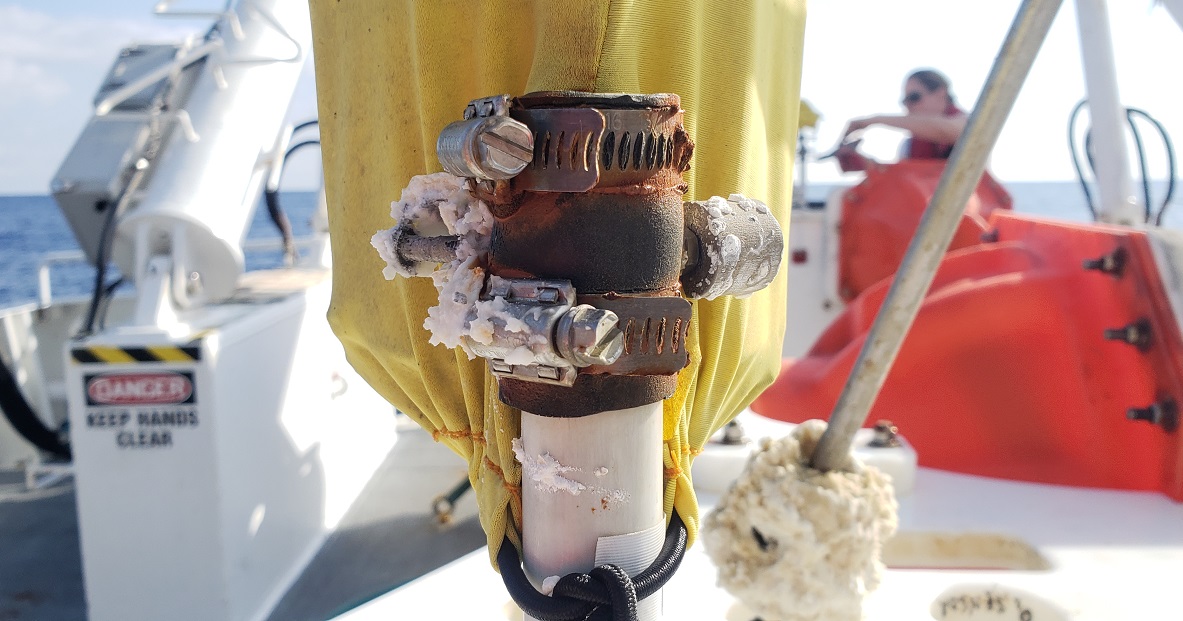

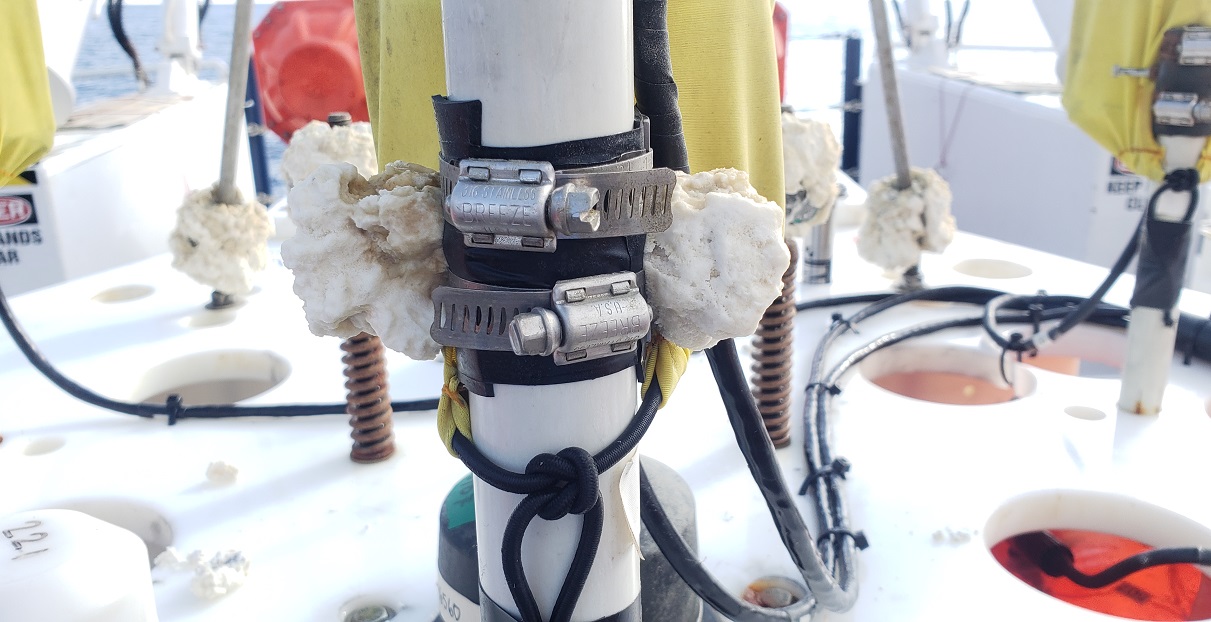

Another lander was successfully picked up this morning, even with the extra waves at this site. The waves made it a little more difficult for the lander to be retrieved and required more people to help grab the lander from the water and get it on board. As we’ve been prepping the recovered landers for the next deployment, we’ve noticed that a lot of the corrosion on the hardware is just surface corrosion. This tends to come off the bolts and washers with a little water and some scrubbing with wire brushes. To prevent the hardware that is holding on sensors from corroding, we use anodes to protect those components.

Anodes are meant to direct the oxidation away from the important gear and act as a sacrifice. They are placed in certain locations on the lander to prevent hardware from corroding away by corroding themselves instead. These pictures show how the anodes that were placed on the lander pole to which the hydrophones are mounted must be secured properly or it will cause damage to the hose clamps that keep the hydrophones secured. In the first image, one of the anodes was not secured properly which caused the hose clamps to rust. The anode on the left is almost completely gone with just the screw being left while the right anode is mostly intact. The second image shows the anodes working properly by corroding away and ultimately protecting the hose clamps.

|

|